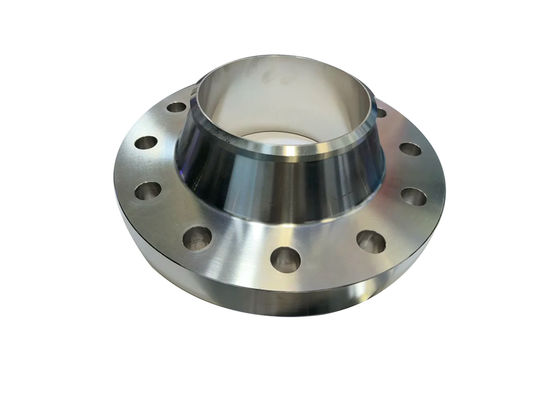

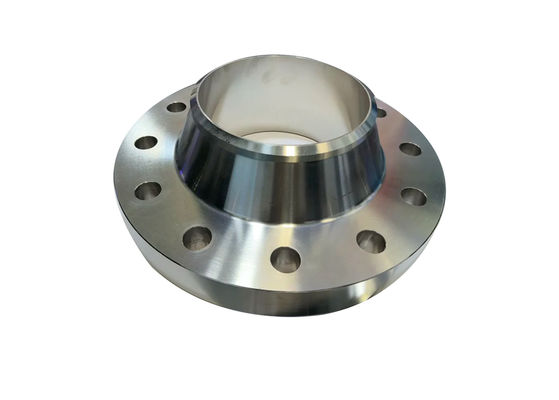

Titanium Weld Neck Flange Pipe Connections for Chemical Ocean Engineering

-

Выделить

Pipe Connections Titanium Weld Neck Flange

,Ocean Engineering Titanium Weld Neck Flange

,Chemical Titanium Weld Neck Flange

-

Обозначение материалаTA1, TA2, TA9, TA10, GR1, GR2, GR7, GR12, GR16, N5, N6, N7 и т. Д.

-

РАЗМЕРNPS 1/2-NP 24

-

ОЭМ/ОДМДоступный

-

ДавлениеClass150 , Class300 , Class600 , Class900 , Class1500 , Class2500

-

ТехникаПоддельный

-

Герметичная поверхностьRF,MFM,TG,FF,RJ

-

Место происхожденияШэньси, Китай

-

Фирменное наименованиеVOTECH

-

СертификацияASME,ANSI

-

Номер моделиNPS 1/2-NP 24

-

Упаковывая деталиЭкспорт стандартного деревянного корпуса или может быть настроен

-

Время доставки7-15 дней

-

Условия оплатыMoneygram, Western Union, T/T, D/P, D/A, L/C.

-

Поставка способности100ton/месяц

Titanium Weld Neck Flange Pipe Connections for Chemical Ocean Engineering

Титановые приварные фланцы с шейкой превосходно подходят для систем, используемых в химической, морской, аэрокосмической промышленности и при транспортировке сред высокой чистоты. Изготовленные с высокой точностью из высококачественного титана, их высокая коррозионная стойкость обеспечивает долговременную структурную целостность и надежность уплотнения в суровых условиях, что значительно снижает затраты на техническое обслуживание и продлевает срок службы оборудования.

Титановые фланцы со сварной шейкой представляют собой трубные фитинги с переходной конструкцией из круглой трубы. Они привариваются к трубе и в основном используются в трубопроводных системах высокого давления, высокой температуры или чувствительных к средам. Расширяющаяся конструкция переходной шейки отдаляет сварной шов от уплотняемой поверхности, уменьшая деформацию сварного шва и улучшая характеристики уплотнения. Такая конструкция значительно повышает герметичность системы и долговременную стабильность в условиях высокого давления, высокой температуры или циклических нагрузок, что делает их идеальным выбором для требовательных применений.

Титановые фланцы с приварной шейкой доступны во всех стандартных размерах в соответствии с вашими потребностями. Кроме того, наши широкие возможности индивидуальной настройки позволяют нам производить фланцы в соответствии с вашими конкретными номинальными значениями давления, стандартами соединений или особыми размерами. Будь то стандартные или индивидуальные, мы стремимся предоставлять высококачественные титановые фланцы, которые точно отвечают вашим потребностям, что делает нас вашим надежным партнером.

|

Номинальный размер |

Внешний диаметр |

Размер соединения |

Толщина фланца |

Большой конец шейки фланца |

Внутренний диаметр фланца |

Высота фланца |

|||||

|

DN |

НПС |

Внешний диаметр фланца |

Диаметр центральной окружности отверстия для болта |

Отверстие для болта |

Болт |

Количество отверстий для болтов |

|||||

|

15 |

1/2 |

21,3 |

90 |

60,3 |

16 |

М14 |

4 |

9,6 |

30 |

15,5 |

46 |

|

20 |

3/4 |

26,9 |

100 |

69,9 |

16 |

М14 |

4 |

11.2 |

38 |

21 |

51 |

|

25 |

1 |

33,7 |

110 |

79,4 |

16 |

М14 |

4 |

12,7 |

49 |

27 |

54 |

|

32 |

1-1/4 |

42,4 |

115 |

88,9 |

16 |

М14 |

4 |

14.3 |

59 |

35 |

56 |

|

40 |

1-1/2 |

48,3 |

125 |

98,4 |

16 |

М14 |

4 |

15,9 |

65 |

41 |

60 |

|

50 |

2 |

60,3 |

150 |

120,7 |

18 |

М16 |

4 |

17,5 |

78 |

52 |

62 |

|

65 |

2-1/2 |

76,1 |

180 |

139,7 |

18 |

М16 |

4 |

20,7 |

90 |

66 |

68 |

|

80 |

3 |

88,9 |

190 |

152,4 |

18 |

М16 |

4 |

22,3 |

108 |

77,5 |

68 |

|

100 |

4 |

114,3 |

230 |

190,5 |

18 |

М16 |

8 |

22,3 |

135 |

101,5 |

75 |

|

125 |

5 |

139,7 |

255 |

215,9 |

22 |

М20 |

8 |

22,3 |

164 |

127 |

87 |

|

150 |

6 |

168,3 |

280 |

241,3 |

22 |

М20 |

8 |

23,9 |

192 |

154 |

87 |

|

200 |

8 |

219,1 |

345 |

298,5 |

22 |

М20 |

8 |

27,0 |

246 |

203 |

100 |

|

250 |

10 |

273 |

405 |

362,0 |

26 |

М24 |

12 |

28,6 |

305 |

255 |

100 |

|

300 |

12 |

323,9 |

485 |

431,8 |

26 |

М24 |

12 |

30,2 |

365 |

303,5 |

113 |

|

350 |

14 |

355,6 |

535 |

476,3 |

30 |

М27 |

12 |

33,4 |

400 |

— |

125 |

|

400 |

16 |

406,4 |

595 |

539,8 |

30 |

М27 |

16 |

35,0 |

457 |

— |

125 |

|

450 |

18 |

457 |

635 |

577,9 |

33 |

М30 |

16 |

38,1 |

505 |

— |

138 |

|

500 |

20 |

508 |

700 |

635,0 |

33 |

М30 |

20 |

41,3 |

559 |

— |

143 |

|

600 |

24 |

610 |

815 |

749,3 |

36 |

М33 |

20 |

46,1 |

663 |

— |

151 |

Титановые приварные фланцы с шейкой обладают чрезвычайно высокой устойчивостью к агрессивным средам, таким как морская вода и ионы хлорида. Их коррозионная стойкость намного превосходит устойчивость нержавеющей стали и углеродистой стали, и они особенно подходят для суровых условий, таких как морская и химическая промышленность.

Незачем. Титановые приварные фланцы с шейкой можно использовать в течение длительного времени без покрытия или катодной защиты, что позволяет избежать риска ржавчины и значительно снизить требования к техническому обслуживанию.